This was my second attempt at a handwired keyboard and the build was largely driven by the terrible results of the stabilizers on my first hand-wire. The shortcoming of those parts got me wondering just how necessary they actually were and if I could work without them. I didn't want to venture into ortholinear and wondered if I could trim everything down to 1.75u or below and still and retain a standard layout. I was already a fan of DSA keycaps so when I realised that Signature Plastics offer custom keycap sizes it made it clear I could make this stabless concept a reality.

I'm really pleased with the end result and the sense of satisfaction from completing it is a huge part of attempting projects like this. It's also worth noting that part of this experiment was about adding extra function buttons underboth thumbs as I felt such a long spacebar was such a waste of potential. Whilst they're fully mapped in my firmware, I've yet to actually find myself needing or wanting to use them. This is likely due to a stubborn muscle memory on my part but it's an interesting takeaway that maybe some norms are just fine as they are.

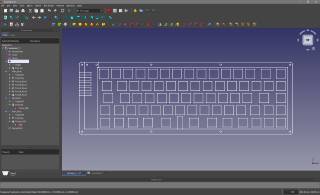

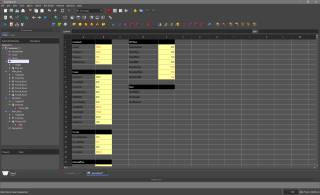

This was my first time building a case from scratch and I opted to use FreeCAD due to the fact that it's freeware and has some parametric functionality that I was interested in trying. This meant I could maintain a spreadsheet of values for various dimensions and the design would update on the fly as I changed them. Whilst this is a really nice feature for tweaking your design it is a little slow to update when working live - which is understandable.

Source Files

Note: These are made available as learning resource for other hobbyists...

FreeCAD source file

Top_Body.svg

Plate_Body.svg

Mid_Body.svg

Base_Body.svg

Beyond stabilizers and their vestigial existence I do have one other bugbear with the industry norm in mechanical keyboards - their height. I honestly feel that if large numbers of your customers require a lump of wrist-supporting material to make the operation comfortable, you've got a design flaw in your product. I can't get this build any lower due to switch standards but I'd like to emply some lower profile switches in my next build. That comes with complications so it's not going to be easy but the challenge is part of the fun. I'd also really like to explore some extra challenges like using a raspberry pi pico, including a small trackball/pad or even writing my own firmware but it's all just a loose set of ideas right now.